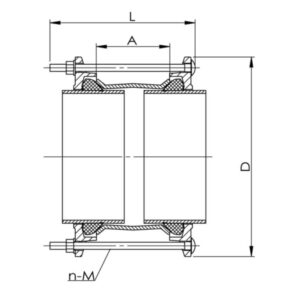

Dresser sleeve Coupling (BOLTED SLEEVE COUPLING)

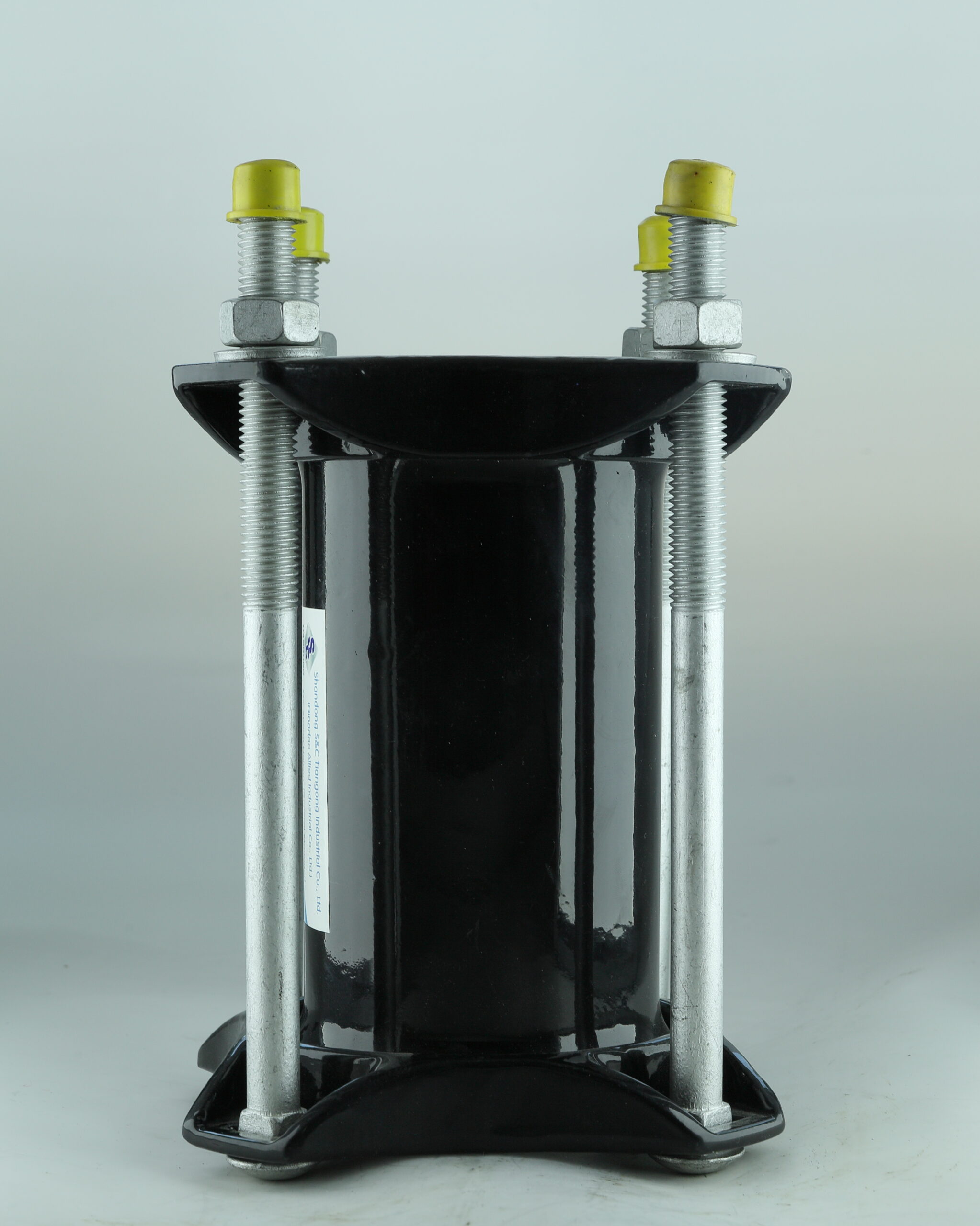

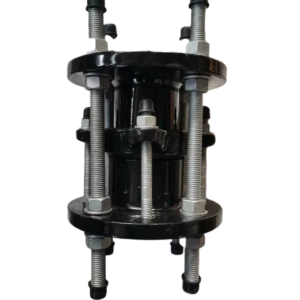

OKVAL brand dresser couplings are used to join Plain End Pipe ,okval bolted sleeve couplings design has sleeves which slide over the pipe ends to which they are to be connected, providing tight coupling between the pipes. okval dresser couplings provide flexible, leak-proof connections that last the life of the pipe its connected to.

"*" indicates required fields

OKVAL Dresser Coupling (BOLTED SLEEVE COUPLING)

■ Features

• Sizes: 2″ – 12″

• Lengths: 2″ – 24″

• Pressure Rating:

• 2″ – 2.5″: 250 psi

• 3″ – 16″: 300 psi

• Material:

• Sleeve: carbon steel ASTM A192

• Bolt/Nut: Galvanized carbon steel ASTM A307

• Follower/gland: ductile iron ASTM A395

• Gasket: Buna (-20°F to 200°F)EPDM / NBR/Viton/ Gasket

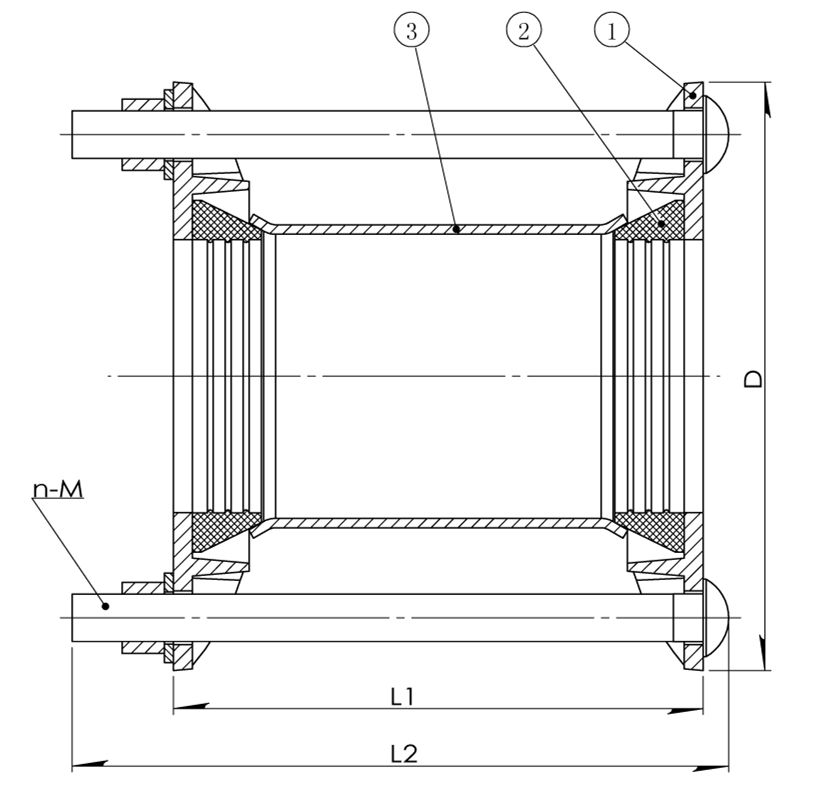

■ Main Parts and Materials

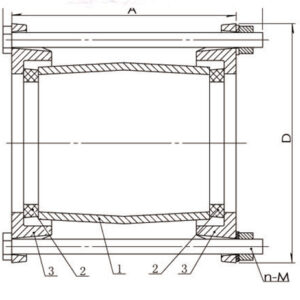

· Cylindrical Middle Ring: This central ring connects the two pipe ends.

· Follower Rings: There are two follower rings, one on each side of the middle ring. They help secure the pipes.

· Resilient Gaskets: These special Dresser compound gaskets absorb vibration and movement while maintaining a seal.

· Steel Track-Head Bolts: These bolts hold the coupling together.

Joints■ Dimensions (mm):

| Size | Pipe OD | OD | Length | Size | Pipe OD | OD | Length | |

| Inch | Inch | mm | mm | Inch | Inch | mm | mm | |

| 2″ | 2.38″ | 60.3 | 4″ | 4″ | 4.5″ | 114.3 | 24″ | |

| 2″ | 2.38″ | 60.3 | 5″ | 5″ | 5.56″ | 139.7 | 12″ | |

| 2″ | 2.38″ | 60.3 | 7″ | 6″ | 6.63″ | 168.3 | 4″ | |

| 2″ | 2.38″ | 60.3 | 12″ | 6″ | 6.63″ | 168.3 | 5″ | |

| 2″ | 2.38″ | 60.3 | 14″ | 6″ | 6.63″ | 168.3 | 7″ | |

| 21/2″ | 2.5″ | 76.1 | 7″ | 6″ | 6.63″ | 168.3 | 12″ | |

| 21/2″ | 2.5″ | 76.1 | 12″ | 6″ | 6.63″ | 168.3 | 16″ | |

| 3″ | 3.5″ | 88.9 | 4″ | 6″ | 6.63″ | 168.3 | 24″ | |

| 3″ | 3.5″ | 88.9 | 5″ | 8″ | 8.63″ | 219.1 | 4″ | |

| 3″ | 3.5″ | 88.9 | 7″ | 8″ | 8.63″ | 219.1 | 12″ | |

| 3″ | 3.5″ | 88.9 | 12″ | 8″ | 8.63″ | 219.1 | 16″ | |

| 3″ | 3.5″ | 88.9 | 16″ | 8″ | 8.63″ | 219.1 | 24″ | |

| 3″ | 3.5″ | 88.9 | 24″ | 10″ | 10.75″ | 273 | 4″ | |

| 4″ | 4.5″ | 114.3 | 4″ | 10″ | 10.75″ | 273 | 12″ | |

| 4″ | 4.5″ | 114.3 | 5″ | 10″ | 10.75″ | 273 | 16″ | |

| 4″ | 4.5″ | 114.3 | 7″ | 12″ | 12.75″ | 323.9 | 4″ | |

| 4″ | 4.5″ | 114.3 | 12″ | 12″ | 12.75″ | 323.9 | 16″ | |

| 4″ | 4.5″ | 114.3 | 16″ | 12″ | 12.75″ | 323.9 | 24″ |

Coplue Dresser Installation Process:

Place the coupling around the pipe ends.

Insert the gaskets between the follower rings and the pipe.

Tighten the bolts to compress the gaskets and create a secure connection.

The resilient gaskets allow for movement while maintaining a leak-free joint.

Flexibility: Dresser couplings accommodate pipe movement due to temperature changes or ground settling.

Quick Installation: They’re easy to install, saving time and labor.

Vibration Absorption: The gaskets absorb harsh vibrations, reducing stress on the pipes.

Remember, Dresser couplings are a reliable choice when you need a flexible and efficient pipe connection!