Documents

Features

Dismantling joints -Ductile iron fittings from OKVAL

Dismantling joint PN6 PN10 PN16 PN25 PN40

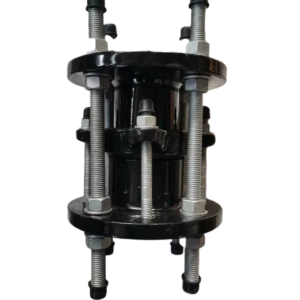

1. Flange: Ductile iron GGG50 according to ISO2531 ISO7005 BS4504 DIN2501 ANSI B16.5

2. Inner pipe: Ductile iron GGG50 Ductile iron GGG50 BS2789 DIN1693 A536

3. Retainer: Ductile iron GGG50

4. Sealing: Gaskets material: For water or Gas: NBR Grade A. For drinking water: EPDM rubber to BS2494: 1990 Type W. For drinking water and sewage: SBR Grade Fdrinking water and sewage: SBR Grade F.

5. Stud: Dacromet Galvanised steel, AISI 304 SS , with plastic caps.

6. Nut: Galvanised steel., AISI 304 SS

7. Washer: Galvanised steel., AISI 304 SS

8. Specification: 40mm-2000mm

9. Finish: Epoxy Coating inside and outside FBE coated RAL 5015 RAL5017 RAL5005 RAL6026 FBE ,mini. 300 microns

Packing: usually DN40-DN350 packed in plywood cases, for size bigger than DN350 fully wrapped packed in plywood pallets. To save space, small joints will packed inside big joints.

Joint de démontage auto buté⠀

Juntas De Desmontaje Auto Bloqueantes

Giunti di smontaggio FLANGIA

Carretes de desmontaje⠀

fonte⠀Fundicin Ductile iron⠀

#dismantlingjoint #ductileirondismantlingjoint #Jointsdedémontage #CARRETESTELESCÓPICOSDEDESMONTAJE #JUNTADEDESMONTAGEM #Демонтажнаявставка #pipefitting #фитинг #instalacióndetuberías #JuntaDeDesmontagemAutoTravada #JuntaFlange #JuntasGibault #FLANGESDEADAPTAÇÃO #UNIONUNIVERSALANTITRACCION

#BridaUnienchufe #okval #ADAPTADORBRIDAUNIVERSA #flangeadaptor #Фланецобжимной #МуфтасоединительнаяДРК #Монтажнаявставка #Фланецдлятрубизсталиичугуна #МУФТА

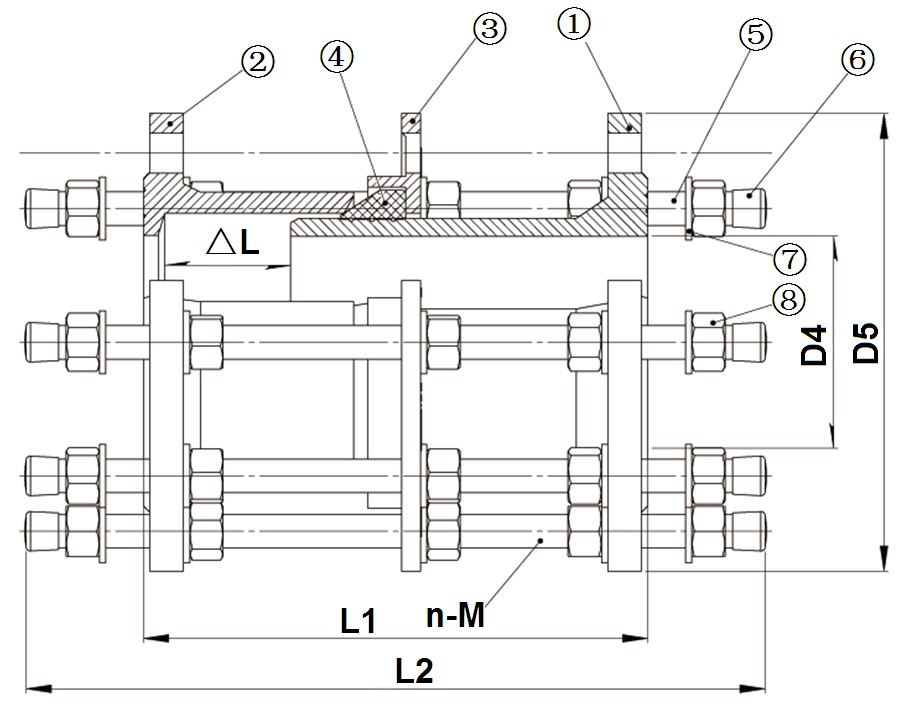

Technical Parameters

Material Specification

| Item No. | Item Name | Material |

| 1 | Long Flange Body | Ductile Iron |

| 2 | Short Flange Body | Ductile Iron |

| 3 | Middle Flange | Ductile Iron |

| 4 | Gasket | Rubber |

| 5 | Stud | Galvanized Steel |

| 6 | Washer | Galvanized Steel |

| 7 | Nut | Galvanized Steel |

Dimensions(mm)

| DN | △L | PN10 | ||||

| L1 | D5 | D4 | n-m | Flange thickness | ||

| 40 | 50 | 210 | 145 | 110 | M16*310*4 | 16+3 |

| 50 | 50 | 215 | 165 | 125 | M16*330*4 | 16+3 |

| 60 | 50 | 215 | 175 | 135 | M16*330*4 | 16+3 |

| 65 | 50 | 215 | 185 | 145 | M16*330*4 | 16+3 |

| 80 | 50 | 225 | 200 | 160 | M16*340*8 | 16+3 |

| 100 | 50 | 225 | 220 | 180 | M16*340*8 | 16+3 |

| 125 | 50 | 225 | 250 | 210 | M16*340*8 | 16+3 |

| 150 | 50 | 225 | 285 | 240 | M20*350*8 | 16+3 |

| 200 | 50 | 235 | 340 | 295 | M20*380*8 | 16+3 |

| 250 | 50 | 250 | 400 | 350 | M20*380*12 | 19+3 |

| 300 | 50 | 265 | 455 | 400 | M20*410*12 | 20.5+3 |

| 350 | 50 | 265 | 505 | 460 | M20*410*16 | 20.5+3 |

| 400 | 50 | 275 | 565 | 515 | M24*450*16 | 20.5+3 |

| 450 | 50 | 295 | 615 | 565 | M24*450*20 | 21.5+3 |

| 500 | 50 | 295 | 670 | 620 | M24*450*20 | 22.5+3 |

| 600 | 50 | 315 | 780 | 725 | M27*480*20 | 25+3 |

| 700 | 50 | 325 | 895 | 840 | M27*480*24 | 27.5+3 |

| 800 | 50 | 340 | 1015 | 950 | M30*500*24 | 30+3 |

| 900 | 50 | 350 | 1115 | 1050 | M30*500*28 | 32.5+3 |

| 1000 | 50 | 360 | 1230 | 1160 | M33*545*28 | 35+3 |

| 1200 | 50 | 370 | 1455 | 1380 | M36*580*32 | 40+3 |

| DN | △L | PN16 | ||||

| L1 | D5 | D4 | n-m | Flange thickness | ||

| 40 | 50 | 210 | 145 | 110 | M16*310*4 | 16+3 |

| 50 | 50 | 215 | 165 | 125 | M16*330*4 | 16+3 |

| 60 | 50 | 215 | 175 | 135 | M16*330*4 | 16+3 |

| 65 | 50 | 215 | 185 | 145 | M16*330*4 | 16+3 |

| 80 | 50 | 225 | 200 | 160 | M16*340*8 | 16+3 |

| 100 | 50 | 225 | 220 | 180 | M16*340*8 | 16+3 |

| 125 | 50 | 225 | 250 | 210 | M16*340*8 | 16+3 |

| 150 | 50 | 225 | 285 | 240 | M20*350*8 | 16+3 |

| 200 | 50 | 235 | 340 | 295 | M20*380*12 | 16+3 |

| 250 | 50 | 250 | 400 | 355 | M24*380*12 | 19+3 |

| 300 | 50 | 265 | 455 | 410 | M24*410*12 | 20.5+3 |

| 350 | 50 | 265 | 520 | 470 | M24*410*16 | 22.5+3 |

| 400 | 50 | 275 | 580 | 525 | M27*450*16 | 24+3 |

| 450 | 50 | 295 | 640 | 585 | M27*450*20 | 26+3 |

| 500 | 50 | 295 | 715 | 650 | M30*460*20 | 27.5+3 |

| 600 | 50 | 315 | 840 | 770 | M33*500*20 | 31+3 |

| 700 | 50 | 325 | 910 | 840 | M33*500*24 | 34.5+3 |

| 800 | 50 | 340 | 1025 | 950 | M36*530*24 | 38+3 |

| 900 | 50 | 350 | 1125 | 1050 | M36*530*28 | 41.5+3 |

| 1000 | 50 | 360 | 1255 | 1170 | M39*570*28 | 45+3 |

| 1200 | 50 | 370 | 1485 | 1390 | M45*620*32 | 52+3 |

| DN | △L | PN25 | ||||

| L1 | D5 | D4 | n-M | Flange thickness | ||

| 40 | 50 | 210 | 145 | 110 | M16*310*4 | 16+3 |

| 50 | 50 | 215 | 165 | 125 | M16*340*4 | 16+3 |

| 60 | 50 | 215 | 175 | 135 | M16*330*4 | 16+3 |

| 65 | 50 | 215 | 185 | 145 | M16*340*4 | 16+3 |

| 80 | 50 | 225 | 200 | 160 | M16*340*8 | 16+3 |

| 100 | 50 | 225 | 235 | 190 | M20*370*8 | 16+3 |

| 125 | 50 | 225 | 270 | 220 | M24*380*8 | 16+3 |

| 150 | 50 | 225 | 300 | 250 | M24*380*8 | 16+3 |

| 200 | 50 | 240 | 360 | 310 | M24*400*12 | 19+3 |

| 250 | 50 | 250 | 425 | 370 | M27*450*12 | 21+3 |

| 300 | 50 | 270 | 485 | 430 | M27*460*16 | 24+3 |

| 350 | 50 | 270 | 555 | 490 | M30*470*16 | 27+3 |

| 400 | 50 | 280 | 620 | 550 | M33*500*16 | 29+3 |

| 450 | 50 | 300 | 670 | 600 | M33*500*20 | 31+3 |

| 500 | 50 | 300 | 730 | 660 | M33*500*20 | 32+3 |

| 600 | 50 | 320 | 845 | 770 | M36*560*20 | 38+3 |

| 700 | 50 | 330 | 960 | 875 | M39*570*24 | 43+3 |

| 800 | 50 | 350 | 1085 | 990 | M45*620*24 | 49+3 |

| 900 | 50 | 360 | 1185 | 1090 | M45*620*28 | 52+3 |

| 1000 | 50 | 370 | 1320 | 1210 | M52*660*28 | 57+3 |

| 1200 | 50 | 380 | 1530 | 1420 | M52*750*32 | 65+3 |